PRODUCTION FACILITES

In 2007, KUWAIT STEEL has accomplished a substantial goal by setting up its own steel making plant that was awarded to M/s. Danieli & C. Officine Meccaniche of Italy. The plant is built in the Shuaiba industrial area and has an annual production capacity of 1.2 million metric tons of steel billets. The steel plant has been designed according to the latest and most advanced technologies within the field of steel plant equipment, characterized by state-of-the-art facilities, effective and compact design layout, optimized logistics and operated by highly experienced personnel.

This allows for the achievement of extremely efficient operation and performance that requires less manpower and low levels of energy consumption, rendering the plant highly competitive.

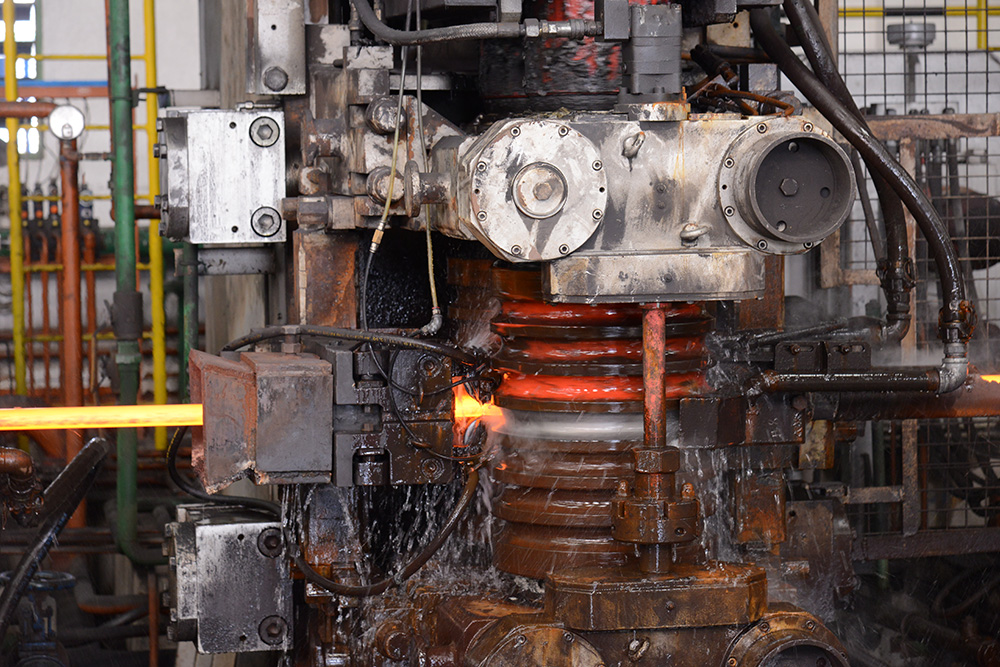

Rolling Mill Plant 1 (RM1)

This rolling mill has an annual production capacity of 800,000 metric tons of reinforcing steel bars with sizes ranging from 8 mm to 40 mm in diameter. Since 2003, KUWAIT STEEL has catered to a large portion of the domestic market demands for this vital product. Due to the high competence of the manufacturing process, the company has been able to attain recognized and stringent international standards such as ASTM, DIN, BS, SASO, KWS GSO ISO 6935-2 in addition to other standards required in the market.

Rolling Mill Plant 2 (RM2)

In 2010, KUWAIT STEEL achieved yet another milestone by acquiring a Rolling Mill Plant in Kuwait that previously had an annual production capacity of 150,000 metric tons. The plant has been completely renovated and upgraded by M/s. Siderimpes (S.R.L) of Italy to increase its annual capacity to 600,000 metric tons of rebar, which is now fully operational, running at full capacity and utilization rates. Both rolling mill plants have a combined annual production capacity of 1.4 million metric tons.

KUWAIT STEEL, in collaboration with Cimprogetti of Italy, commissioned its Lime & Dololime Calcination Plant in January 2020 to produce high-grade Calcined lime and Dololime for captive consumption with a combined annual production capacity of 119,000 metric tons. Both high grade Lime and Dololime are used extensively as a flux in the refining of the steel. In the Electric Arc Furnace, Lime is particularly useful in removing phosphorous, sulphur, silica, and an unsignificant amount of manganese.

Lime & Dololime are also used to perform other critical functions such as fine-tuning steel chemistry, lowering oxygen content, reducing the inclusions trapped by the slag, adjusting steel temperature, removing additional impurities, and the prevention of reabsorption of impurities from slags.

As part of its efforts to achieve its goal of environmental sustainability, the steel industry globally is striving toward optimising scrap utilisation in steel production. Increased scrap usage decreases the demand for new resource extraction, and hence minimises the environmental footprint. KUWAIT STEEL went one step further and designed its steel making facility so that over 80% of steel scrap can be used as raw materials feed for its Electric Arc Furnace (EAF). One of the company's strategic focuses has been the development of local industry, and KUWAIT STEEL continues to increase its share of scrap metal purchases from local sources.

It is necessary to prepare the scrap before it is fed into the steelmaking furnace, and larger scrap pieces must be processed to the right size to fit into the furnace; to meet this criterion, KUWAIT STEEL successfully completed the commissioning of its Scrap Processing Facility (Shear Machine) supplied by DANIELI HENSCHEL in 2016. The facility is of CIB type with a side compression box most adapted for processing heavy and bulk scrap metal. This shear machine allows a quite precise adjustment of the shearing length while cutting at a force of 1250/MT at 0.1 to 1.5m in length and cutting rate of 5.5 cuts/min to achieve an hourly production of approximately 60/ MT. The scrap processing facility plays an integral part in the recycling of scrap metal generated in the state of Kuwait, reducing the company's dependency on imported scrap.